PRECISION COLD-DRAWN SEAMLESS TUBES

Cold drawing can be defined as the process of re-drawing applied to semi-manufactured and hot-drawn seamless main tubes with the primary purpose of improving surface quality and linearity in addition to achieving more precise dimensions and tolerances, easier shaping, and the desired rigidity and softness values.

In other words, the process of re-drawing applied to hot-drawn seamless main tubes through computer-controlled integrated machines repetitiously until successive target values are reached can be described in general terms as the "method of achieving the desired measurements and more precise tolerances".

PRECISION COLD-DRAWN STEEL TUBES

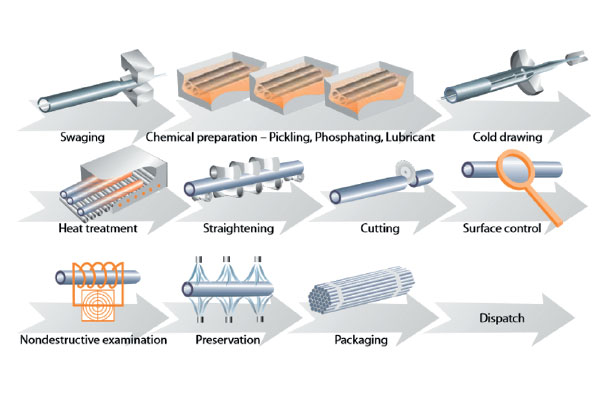

In the production of cold-drawn seamless tubes, in addition to the origin, content and quality of the raw material (i.e., the main tube product), the technical competence and expertise of the manufacturer, the cleanliness of machine lines and the calibration of measuring devices are very important as well. Main tubes initially go through processes of bath and tube end preparation through surface preparation cleaning in order to remove the oxide layers and shells on their surface, followed by the cold drawing processes carried out with the stages of production listed below. This process can be repeated with multiple draws in order to reach the desired technical features and specified lengths. If necessary, the tubes are subjected to heat treatment once again during or after production. Performing this process, particularly in fully-automatic integrated machines, is of importance in order to reach the desired level of quality. Afterwards, the tubes are cut and the process is finalized.

In the final stage of production, the tubes are subjected to the necessary controls and tests before being packaged in line with customer demands using hexagonal ties covered with protective oil and with both ends capped, preferably not exceeding a maximum of 2 tons, and durable products such as razor wires to protect the tube surface, and prepared for shipment.

Cold-drawn seamless steel tubes, which are resistant to high pressures, are produced in various qualities and heat treatment properties, in compliance with the EN 10305-1 or EN 10305-4 standards based on their intended use

COLD-DRAWN SEAMLESS TUBES FOR PRECISION APPLICATIONS

| EN 10305-1 Cold-Drawn Seamless Tubes | EN 10305-4 Cold-Drawn Seamless Hydraulic and Pneumatic Line/Installation Tubes |

|---|---|

| No marking on the tube surface is required. | Marking on the tube surface is required. |

| Eddy Current/crack control tests are not performed. | Eddy Current/crack control tests are performed. |

| Tube lengths are submitting in random lengths. | Tube lengths are fixed Lenght = 6.000 mm. as standardized. |

| End of tubes are without plastic caps | End of tubes closed by plastic cap.. |

|

If not required, a certificate is issued according to mill certficate 2.2 EN 10214. |

EN 20214, 3.1 inspecition certficate has to be prepared by manufacturer. |

EN 10305-4 COLD-DRAWN SEAMLESS HYDRAULIC AND PNEUMATIC LINE/INSTALLATION TUBES

Hydraulic line tubes, one of the hydraulic main system components, are manufactured from seamless, flexible, resistant and high-quality steel tubes that distribute the oil/fluid in their storage tank to receivers, and later back to the main tank without leakage.

EN 10305-4 hydraulic line tubes are subjected to Eddy Current tests, manufactured in accordance with the E235+N (St37-4 NBK) or E355+N (St52-4 NBK) quality standards at a standard length of 6 meters with straight-cut ends (both ends sealed), and presented with a 3.1 manufacturer test certificate. They are easily shaped due to being normalized and flexible.

Surfaces of HPL tubes can be classified as follows;

- Oiled

- Phosphated and slightly oiled

- Electrolytically galvanized (Cr6 Free Zn 12 Micron)

As "HYDRO TUBE", we stock European hydraulic pipes that are produced at the highest quality in accordance with the intended uses, purposes, sizes and required dimensions.

ELECTROLYTICALLY GALVANIZED OUTER SURFACE (CR6 FREE ZN 12 MICRON)

We stock imported galvanized hydraulic line tubes in accordance with the EN10305-4 (E235+N) and (E355+N) quality standards. Galvanized steel tubes are produced by the manufacturer in accordance with the EN ISO 2081:2018 quality standards using the electroplated coating method at high resistance values that protect the steel from corrosion and deterioration, and at various specialized thicknesses. Zn 12 micron galvanized tubes possess a stronger, longer-lasting steel surface quality against potential corrosion and deterioration due to external environments.

“HYDRO TUBE" imports Zn 12 micron galvanized tubes, which have the highest resistance value and duration against corrosion with the aim of providing its customers with higher-quality products.

GALVANIZED/CR6 FREE ZN 12 MICRON HPL TUBE DIMENSIONS AND WEIGHTS

| Outside Diameter [mm] | Wall Thickness [mm] | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0,5 | 0,75 | 0,89 | 1 | 1,24 | 1,5 | 1,65 | 2 | 2,11 | 2,3 | 2,5 | 3 | 3,5 | 4 | 5 | |

| 4 | 0,043 | 0,06 | 0,074 | ||||||||||||

| 5 | 0,079 | 0,099 | |||||||||||||

| 6 | 0,097 | 0,123 | 0,166 | 0,197 | |||||||||||

| 6,35 | 0,12 | 0,156 | |||||||||||||

| 8 | 0,173 | 0,240 | 0,296 | 0,339 | |||||||||||

| 9,52 | 0,189 | 0,235 | 0,320 | ||||||||||||

| 10 | 0,222 | 0,314 | 0,395 | 0,462 | |||||||||||

| 12 | 0,271 | 0,388 | 0,493 | ||||||||||||

| 12,7 | 0,259 | 0,350 | 0,450 | 0,551 | |||||||||||

| 13 | 0,296 | 0,425 | 0,543 | ||||||||||||

| 13,5 | 0,635 | ||||||||||||||

| 14 | 0,321 | 0,462 | 0,592 | 0,709 | 0,814 | ||||||||||

| 15 | 0,345 | 0,499 | 0,641 | 0,771 | 0,888 | ||||||||||

| 15,87 | 0,329 | 0,445 | 0,579 | 0,716 | |||||||||||

| 16 | 0,370 | 0,536 | 0,690 | 0,832 | 0,961 | ||||||||||

| 18 | 0,610 | 0,789 | 0,956 | 1,100 | |||||||||||

| 20 | 0,469 | 0,684 | 0,888 | 1,079 | 1,258 | ||||||||||

| 22 | 0,758 | 0,986 | 1,202 | 1,406 | 1,597 | ||||||||||

| 25 | 0,869 | 1,134 | 1,387 | 1,628 | 2,071 | ||||||||||

| 28 | 0,980 | 1,282 | 1,572 | 1,85 | 2,367 | ||||||||||

| 30 | 1,381 | 1,997 | 2,287 | 2,565 | |||||||||||

| 32 | 1,488 | ||||||||||||||

| 35 | 1,628 | 2,367 | 3,058 | ||||||||||||

| 38 | 1,866 | 2,589 | 3,354 | 4,069 | |||||||||||

| 42 | 1,973 | 2,885 | 3,748 | ||||||||||||

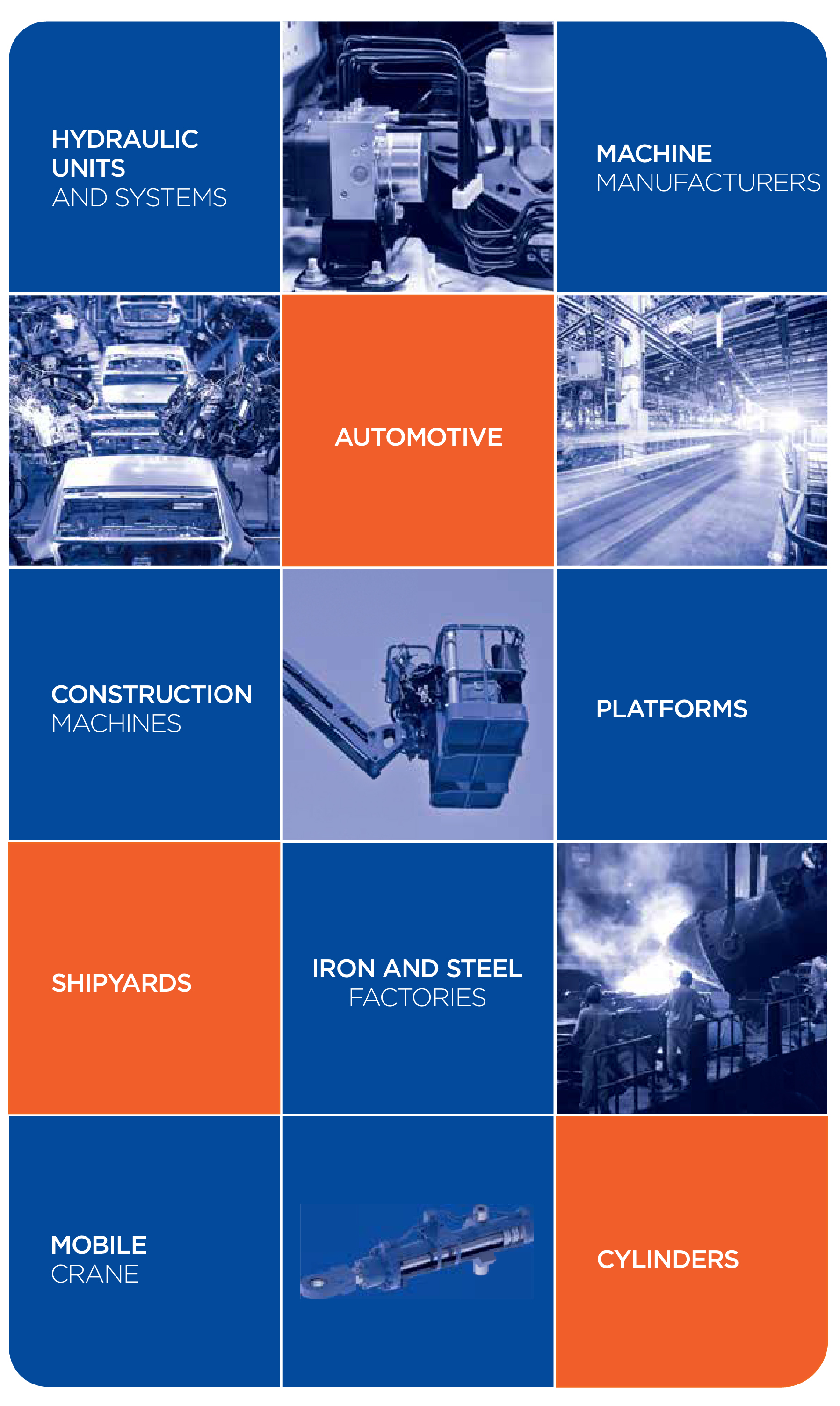

AREAS OF USAGE FOR EN 10305-4 COLD-DRAWN SEAMLESS HPL/INSTALLATION TUBES

GENERAL TEST METHODS FOR COLD-DRAWN SEAMLESS TUBES

| Mandatory Tests | Optional Tests |

|---|---|

| Chemical Tests | Certifications awarded based on the tube, its quality and further tests that can be conducted under the supervision of independent organizations (such as 3.2 Lloyd's, TUV, GL) based on the agreement between the customer and the factory before production. |

| Mechanical Tests 20 °C | |

| Eddy Current Test in accordance with EN 10893-1 | |

| Visual inspection and measuremental tests | |

| Flaring Flattening tests |

HEAT TREATMENT STATUS

| EN 10305-1 | EN 10305-4 | Symbol Definitions | DIN 2391 (Former Norm) |

|---|---|---|---|

| C+ | Cold-Drawn/Rigid | BK+S | |

| LC+ | SCold-Drawn/Soft | BKW | |

| SR+ | Cold-Drawn/Normalized | BKS | |

| A | Tempered | GBK | |

| N+ | Normalized/Flexible | NBK | |

| Q+T | Hardened and Tempered | QT |

CHEMICAL COMPOSITION AND MECHANICAL PROPERTIES

| Standart | Steel Grade | Chemical Composition (%) | Mechanical Properties | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C [max] | Si [max] | Mn [max] | P [max] | S [max] | Yield Strength/Re | Tensile Strength/Rm | Elongation/A5 | |||

| Mpa [min] | Mpa [min] | Mpa [max] | % [min] | |||||||

| EN10305-1 | E235 | 0,17 | 0,35 | 1,20 | 0,025 | 0,025 | 235 | 340 | 480 | 25 |

| E355 | 0,22 | 0,55 | 1,60 | 0,025 | 0,025 | 355 | 490 | 630 | 22 | |

| EN10305-4 | E 235 | 0,17 | 0,35 | 1,20 | 0,025 | 0,015 | 235 | 350 | 480 | 25 |

| E 355 | 0,22 | 0,55 | 1,60 | 0,025 | 0,015 | 355 | 490 | 630 | 22 | |

GENERAL DIMENSION AND WEIGHT TABLE FOR COLD-DRAWN SEAMLESS TUBES IN ACCORDANCE WITH EN STANDARDS

| Outside Diameter [mm] | Wall Thickness[mm] | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0,5 | 1 | 1,5 | 2 | 2,5 | 3 | 3,5 | 4 | 4,5 | 5 | 5,5 | 6 | 7 | 8 | 9 | 10 | 11.0 | 12.0 | 13.0 | |

| Tube Weights [kg/m] | |||||||||||||||||||

| 4 | 0,043 | 0,074 | |||||||||||||||||

| 5 | 0,055 | 0,099 | |||||||||||||||||

| 6 | 0,068 | 0,123 | 0,166 | 0,197 | |||||||||||||||

| 7 | 0,08 | 0,148 | 0,203 | 0,247 | |||||||||||||||

| 8 | 0,093 | 0,173 | 0,24 | 0,296 | 0,339 | 0,37 | |||||||||||||

| 9 | 0,105 | 0,197 | 0,277 | 0,345 | 0,401 | 0,444 | |||||||||||||

| 10 | 0,117 | 0,222 | 0,314 | 0,395 | 0,462 | 0,518 | 0,561 | ||||||||||||

| 12 | 0,142 | 0,271 | 0,388 | 0,493 | 0,586 | 0,666 | 0,734 | 0,789 | |||||||||||

| 14 | 0,166 | 0,321 | 0,462 | 0,592 | 0,709 | 0,814 | 0,906 | 0,986 | 1,054 | 1,11 | |||||||||

| 15 | 0,179 | 0,345 | 0,499 | 0,641 | 0,771 | 0,888 | 0,993 | 1,085 | 1,165 | 1,233 | |||||||||

| 16 | 0,191 | 0,37 | 0,536 | 0,691 | 0,832 | 0,962 | 1,079 | 1,184 | 1,276 | 1,356 | |||||||||

| 18 | 0,216 | 0,419 | 0,61 | 0,789 | 0,956 | 1,11 | 1,252 | 1,381 | 1,498 | 1,603 | |||||||||

| 20 | 0,24 | 0,469 | 0,684 | 0,888 | 1,079 | 1,258 | 1,424 | 1,578 | 1,72 | 1,85 | 1,967 | 2,071 | |||||||

| 22 | 0,265 | 0,518 | 0,758 | 0,986 | 1,202 | 1,406 | 1,597 | 1,777 | 1,942 | 2,096 | 2,24 | 2,367 | |||||||

| 24 | 0,29 | 0,567 | 0,832 | 1,085 | 1,326 | 1,554 | 1,769 | 1,973 | 2,164 | 2,343 | 2,509 | 2,663 | |||||||

| 25 | 0,302 | 0,592 | 0,869 | 1,134 | 1,387 | 1,628 | 1,856 | 2,072 | 2,275 | 2,446 | 2,645 | 2,811 | |||||||

| 26 | 0,314 | 0,617 | 0,906 | 1,184 | 1,449 | 1,702 | 1,942 | 2,17 | 2,386 | 2,59 | 2,78 | 2,959 | |||||||

| 28 | 0,666 | 0,98 | 1,282 | 1,572 | 1,85 | 2,115 | 2,368 | 2,608 | 2,836 | 3,052 | 3,255 | ||||||||

| 30 | 0,715 | 1,054 | 1,381 | 1,695 | 1,988 | 2,287 | 2,565 | 2,83 | 3,083 | 3,323 | 3,551 | 3,97 | |||||||

| 32 | 0,764 | 1,128 | 1,48 | 1,819 | 2,146 | 2,46 | 2,762 | 3,052 | 3,329 | 3,594 | 3,847 | 4,316 | 4,735 | ||||||

| 35 | 0,838 | 1,239 | 1,628 | 2,004 | 2,367 | 2,719 | 3,058 | 3,385 | 3,699 | 4,001 | 4,291 | 4,834 | 5,327 | ||||||

| 36 | 0,863 | 1,276 | 1,677 | 2,065 | 2,441 | 2,805 | 3,157 | 3,496 | 3,822 | 4,137 | 4,439 | 5,006 | 5,524 | ||||||

| 38 | 0,912 | 1,35 | 1,766 | 2,189 | 2,589 | 2,978 | 3,354 | 3,718 | 4,069 | 4,408 | 4,735 | 5,352 | 5,919 | ||||||

| 40 | 0,962 | 1,424 | 1,874 | 2,312 | 2,737 | 3,15 | 3,551 | 3,94 | 4,316 | 4,68 | 5,031 | 5,697 | 6,313 | 6,88 | 7,398 | 7,867 | |||

| 42 | 1,011 | 1,498 | 1,973 | 2,435 | 2,885 | 3,323 | 3,749 | 4,162 | 4,562 | 4,951 | 5,327 | 6,042 | 6,708 | 7,324 | 7,892 | 8,41 | |||

| 45 | 1,085 | 1,609 | 2,12 | 2,62 | 3,107 | 3,582 | 4.044 | 4,494 | 4,932 | 5,358 | 5,77 | 6,56 | 7,3 | 7,99 | 8,631 | 9,223 | |||

| 46 | 1,11 | 1,646 | 2,17 | 2,682 | 3,181 | 3,668 | 4,143 | 4,605 | 5,055 | 5,493 | 5,919 | 6,733 | 7,497 | 8,212 | 8,878 | 9,949 | |||

| 48 | 1,159 | 1,72 | 2,269 | 2,805 | 3,329 | 3,841 | 4,34 | 4,827 | 5,302 | 5,764 | 6,215 | 7,078 | 7,892 | 8,656 | 9,371 | 10,04 | |||

| 50 | 1,208 | 1,794 | 2,368 | 2,929 | 3,477 | 4,014 | 4,538 | 5,049 | 5,549 | 6,036 | 6,511 | 7,423 | 8,286 | 9,1 | 9,864 | 10,58 | 11,25 | ||

| 52 | 1,868 | 2,466 | 3,052 | 3,625 | 4,188 | 4,735 | 5,271 | 5,795 | 6,307 | 6,807 | 7,768 | 8,681 | 9,544 | 10,36 | 11,12 | 11,84 | 12,5 | ||

| 55 | 1,979 | 2,614 | 3,237 | 3,847 | 4,445 | 5,031 | 5,604 | 6,165 | 6,714 | 7,25 | 8,286 | 9,273 | 10,21 | 11,1 | 11,94 | 12,73 | 13,47 | ||

| 58 | 2,09 | 2,762 | 3,422 | 4,069 | 4,704 | 5,327 | 5,937 | 6,535 | 7,121 | 7,694 | 8,804 | 9,865 | 10,88 | 11,84 | 12,75 | 13,61 | 14,43 | ||

| 60 | 2,164 | 2,861 | 3,545 | 4,217 | 4,877 | 5,524 | 6,159 | 6,782 | 7,392 | 7,99 | 9,149 | 10,26 | 11,32 | 12,33 | 13,29 | 14,21 | 15,07 | ||

| 62 | 2,238 | 2,959 | 3,668 | 4,365 | 5,049 | 5,721 | 6,381 | 7,028 | 7,663 | 8,286 | 9,495 | 10,65 | 11,76 | 12,82 | 13,84 | 14,8 | 15,71 | ||

| 65 | 2,349 | 3,107 | 3,853 | 4,587 | 5,308 | 6,017 | 6,714 | 7,398 | 8,07 | 8,73 | 10,01 | 11,25 | 12,43 | 13,56 | 14,65 | 15,68 | 16,67 | ||

| 70 | 2,534 | 3,354 | 4,162 | 4,957 | 5,74 | 6,511 | 7,269 | 8,015 | 8,749 | 9,47 | 10,88 | 12,23 | 13,54 | 14,8 | 16,01 | 17,16 | 18,27 | ||

| 75 | 2,719 | 3,601 | 4,47 | 5,327 | 6,172 | 7,004 | 7,824 | 8,632 | 9,427 | 10,21 | 11,74 | 13,22 | 14,65 | 16,03 | 17,36 | 18,64 | 19,88 | ||

| 80 | 2,904 | 3,874 | 4,778 | 5,697 | 6,603 | 7,497 | 8,379 | 9,248 | 10,11 | 10,95 | 12,6 | 14,21 | 15,76 | 17,26 | 18,72 | 20,12 | 21,48 | ||

| 85 | 3,089 | 4,094 | 5,086 | 6,067 | 7,035 | 7,99 | 8,934 | 9,865 | 10,78 | 11,69 | 13,47 | 15,19 | 16,87 | 18,5 | 20,07 | 21,6 | 23,08 | ||

| 90 | 3,274 | 4,34 | 5,395 | 6,437 | 7,466 | 8,484 | 9,489 | 10,48 | 11,46 | 12,43 | 14,33 | 16,18 | 17,98 | 19,73 | 21,43 | 23,08 | 24,69 | ||

| 95 | 4,587 | 5,703 | 6,807 | 7,898 | 8,977 | 10,04 | 11,1 | 12,14 | 13,17 | 15,19 | 17,16 | 19,09 | 20,96 | 22,79 | 24,56 | 26,29 | |||

| 100 | 4,834 | 6,011 | 7,176 | 8,329 | 9,47 | 10,6 | 11,71 | 12,82 | 13,91 | 16,06 | 18,15 | 20,2 | 22,2 | 24,14 | 26,04 | 27,89 | |||

| 110 | 5,327 | 6,628 | 7,916 | 9,193 | 10,46 | 11,71 | 12,95 | 14,17 | 15,39 | 17,78 | 20,12 | 22,42 | 24,66 | 26,86 | 29 | 31,1 | |||

| 120 | 5,82 | 7,244 | 8,656 | 10,06 | 11,44 | 12,82 | 14,18 | 15,53 | 16,87 | 19,51 | 22,1 | 24,64 | 27,13 | 29,57 | 31,96 | 34,3 | |||

| 125 | 9,026 | 10,49 | 11,94 | 13,37 | 14,8 | 16,21 | 17,61 | 20,37 | 23,08 | 25,75 | 28,36 | 30,93 | 33,44 | 35,91 | |||||

EN 10305-4 HPL TUBES MEASUREMENT TABLE

| Outside Diameter [mm] | Wall Thickness [mm] | Inner Diameter [mm] | Inside Diameter Tolerance | Outside Diameter Tolerance | Cross-Sectional Area [cm2] | Outside Diameter [mm] | Wall Thickness [mm] | Inner Diameter [mm] | Inside Diameter Tolerance | Outside Diameter Tolerance | Cross-Sectional Area [cm2] | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 6 | 1 | 4 | ± 0,12 | ± 0,08 | 0,13 | 28 | 1,5 | 25 | ± 0,08 | ± 0,08 | 4,91 | |

| 1,5 | 3 | ± 0,15 | ± 0,08 | 0,071 | 2 | 24 | ± 0,08 | ± 0,08 | 4,52 | |||

| 2 | 2 | ± 0,15 | ± 0,08 | 0,031 | 3 | 22 | ± 0,15 | ± 0,08 | 3,80 | |||

| 8 | 1 | 6 | ± 0,10 | ± 0,08 | 0,28 | 4 | 20 | ± 0,15 | ± 0,08 | 3,14 | ||

| 1,5 | 5 | ± 0,10 | ± 0,08 | 0,20 | 5 | 18 | ± 0,15 | ± 0,08 | 2,55 | |||

| 2 | 4 | ± 0,15 | ± 0,08 | 0,13 | 30 | 2 | 26 | ± 0,08 | ± 0,08 | 5,31 | ||

| 10 | 1 | 8 | ± 0,08 | ± 0,08 | 0,50 | 2,5 | 25 | ± 0,08 | ± 0,08 | 4,91 | ||

| 1,5 | 7 | ± 0,12 | ± 0,08 | 0,38 | 3 | 24 | ± 0,15 | ± 0,08 | 4,52 | |||

| 2 | 6 | ± 0,15 | ± 0,08 | 0,28 | 4 | 22 | ± 0,15 | ± 0,08 | 3,80 | |||

| 2,5 | 5 | ± 0,15 | ± 0,08 | 0,20 | 5 | 20 | ± 0,15 | ± 0,08 | 3,14 | |||

| 12 | 1 | 10 | ± 0,08 | ± 0,08 | 0,79 | 6 | 18 | ± 0,15 | ± 0,08 | 2,55 | ||

| 1,5 | 9 | ± 0,10 | ± 0,08 | 0,64 | 35 | 2 | 31 | ± 0,15 | ± 0,15 | 7,55 | ||

| 2 | 8 | ± 0,12 | ± 0,08 | 0,50 | 3 | 29 | ± 0,15 | ± 0,15 | 6,61 | |||

| 2,5 | 7 | ± 0,15 | ± 0,08 | 0,38 | 4 | 27 | ± 0,15 | ± 0,15 | 5,73 | |||

| 3 | 6 | ± 0,15 | ± 0,08 | 0,28 | 5 | 25 | ± 0,15 | ± 0,15 | 4,91 | |||

| 14 | 1 | 12 | ± 0,08 | ± 0,08 | 1,13 | 6 | 23 | ± 0,15 | ± 0,15 | 4,16 | ||

| 1,5 | 11 | ± 0,08 | ± 0,08 | 0,95 | 38 | 2,5 | 33 | ± 0,15 | ± 0,15 | 8,55 | ||

| 2 | 10 | ± 0,12 | ± 0,08 | 0,79 | 3 | 32 | ± 0,15 | ± 0,15 | 8,04 | |||

| 3 | 8 | ± 0,15 | ± 0,08 | 0,50 | 4 | 30 | ± 0,15 | ± 0,15 | 7,07 | |||

| 15 | 1 | 13 | ± 0,08 | ± 0,08 | 1,33 | 5 | 28 | ± 0,15 | ± 0,15 | 6,16 | ||

| 1,5 | 12 | ± 0,08 | ± 0,08 | 1,13 | 6 | 26 | ± 0,15 | ± 0,15 | 5,31 | |||

| 2 | 11 | ± 0,10 | ± 0,08 | 0,95 | 42 | 2 | 38 | ± 0,20 | ± 0,20 | 11,34 | ||

| 3 | 9 | ± 0,15 | ± 0,08 | 0,64 | 3 | 36 | ± 0,20 | ± 0,20 | 10,18 | |||

| 16 | 1,5 | 13 | ± 0,08 | ± 0,08 | 1,33 | 4 | 34 | ± 0,20 | ± 0,20 | 9,08 | ||

| 2 | 12 | ± 0,15 | ± 0,08 | 1,13 | 50 | 4 | 42 | ± 0,20 | ± 0,20 | 13,85 | ||

| 2,5 | 11 | ± 0,12 | ± 0,08 | 0,95 | 5 | 40 | ± 0,20 | ± 0,20 | 12,57 | |||

| 3 | 10 | ± 0,15 | ± 0,08 | 0,79 | 6 | 38 | ± 0,20 | ± 0,20 | 11,34 | |||

| 18 | 1,5 | 15 | ± 0,08 | ± 0,08 | 1,77 | 8 | 34 | ± 0,20 | ± 0,20 | 9,08 | ||

| 2 | 14 | ± 0,08 | ± 0,08 | 1,54 | 55 | 4 | 47 | ± 0,25 | ± 0,25 | 17,34 | ||

| 2,5 | 13 | ± 0,15 | ± 0,08 | 1,33 | 6 | 43 | ± 0,25 | ± 0,25 | 14,51 | |||

| 3 | 12 | ± 0,15 | ± 0,08 | 1,13 | 8 | 39 | ± 0,25 | ± 0,25 | 11,95 | |||

| 20 | 1,5 | 17 | ± 0,08 | ± 0,08 | 2,27 | 10 | 35 | ± 0,25 | ± 0,25 | 9,62 | ||

| 2 | 16 | ± 0,08 | ± 0,08 | 2,01 | 60 | 5 | 50 | ± 0,25 | ± 0,25 | 19,63 | ||

| 2,5 | 15 | ± 0,15 | ± 0,08 | 1,77 | 8 | 44 | ± 0,25 | ± 0,25 | 15,20 | |||

| 3 | 14 | ± 0,15 | ± 0,08 | 1,54 | 10 | 40 | ± 0,25 | ± 0,25 | 12,57 | |||

| 4 | 12 | ± 0,15 | ± 0,08 | 1,13 | 12,5 | 35 | ± 0,25 | ± 0,25 | 9,62 | |||

| 22 | 1,5 | 19 | ± 0,08 | ± 0,08 | 2,84 | 70 | 5 | 60 | ± 0,30 | ± 0,30 | 28,26 | |

| 2 | 18 | ± 0,08 | ± 0,08 | 2,55 | 8 | 54 | ± 0,30 | ± 0,30 | 22,89 | |||

| 3 | 16 | ± 0,15 | ± 0,08 | 2,01 | 10 | 50 | ± 0,30 | ± 0,30 | 19,63 | |||

| 25 | 2 | 21 | ± 0,08 | ± 0,08 | 3,46 | 12,5 | 45 | ± 0,30 | ± 0,30 | 15,90 | ||

| 2,5 | 20 | ± 0,08 | ± 0,08 | 3,14 | 80 | 6 | 68 | ± 0,35 | ± 0,35 | 36,30 | ||

| 3 | 19 | ± 0,15 | ± 0,08 | 2,84 | 8 | 64 | ± 0,35 | ± 0,35 | 32,15 | |||

| 4 | 17 | ± 0,15 | ± 0,08 | 2,27 | 10 | 60 | ± 0,35 | ± 0,35 | 28,26 | |||

| 5 | 15 | ± 0,15 | ± 0,08 | 1,77 | 12,5 | 55 | ± 0,35 | ± 0,35 | 23,75 |